Active Harmonic Filters: Ensuring Energy Regulatory Compliance in Australia

On This Page:

- Introduction

- Australian Standards Compliance

- Harmonics and Power Quality

- The Role of Active Harmonic Filters

- Ensuring Compliance Through Active Harmonic Filters

- Benefits Beyond Compliance

- Implementing Active Harmonic Filters

- Quality Energy: Power Quality Solutions Experts Since 1989

- Quality Energy's Active Harmonic Filters in Action

- Conclusion

In Australia, the AS/NZS61000.3.3 standard governs the acceptable level of harmonic voltage distortion and aligns with the IEEE519 guidelines. If your power supplier or distributor is dissatisfied with the amount of voltage distortion at the point of common coupling (PCC), they may require harmonic filtering to comply with Australian standards. Active Harmonic Filters (AHFs) have emerged as a solution that not only enhances power quality but also helps industries adhere to regulatory requirements in Australia. This article dives into the regulatory landscape surrounding power quality in the country and explores how AHFs serve as an indispensable tool for businesses aiming to ensure compliance, sidestep penalties, and reduce energy costs.

Australian Standards Compliance for Active Harmonic Filters

Australia's commitment to maintaining high standards of power quality is reflected in its regulatory framework. The Australian Energy Regulator (AER) and various state-based regulators have established standards that businesses must adhere to. These standards focus on parameters such as voltage quality, harmonic distortion levels, and power factor. Non-compliance with these standards not only affects operational efficiency but also attracts financial penalties in the form of demand charges.

In Australia, the AS/NZS 61000.3.6 standard governs the acceptable level of harmonic voltage distortion and aligns with the IEEE 519 guidelines. If your power supplier or distributor is dissatisfied with the amount of voltage distortion at the point of common coupling (PCC), they may require harmonic filtering to comply with the Australian Standards. By managing the currents or impedances in the industrial facility, harmonic voltages on the utility distribution can be regulated since these voltages arise from the flow of harmonic currents through distribution system impedances.

Harmonics and Power Quality

Harmonics is a byproduct of non-linear loads and power electronics, which can disrupt power quality significantly. These distorted waveforms not only impact equipment performance but also strain the entire electrical distribution system. Harmonic currents can cause overheating, equipment malfunction, and unnecessary energy losses. When harmonics are eliminated or minimised, power quality will improve.

The Role of Active Harmonic Filters

Active Harmonic Filters, or AHFs, are dynamic devices designed to counteract harmonics and maintain a clean power supply. AHFs continually monitor the electrical waveform and inject counteractive currents to cancel out harmonic currents, ensuring a power supply that aligns with regulatory standards. This active intervention addresses a range of harmonic frequencies and prevents excessive distortion, safeguarding equipment and compliance.

Ensuring Compliance Through Active Harmonic Filters

- Voltage Quality Enhancement: Harmonic distortions can lead to voltage instability, affecting both equipment performance and regulatory compliance. AHFs stabilise voltage levels, ensuring businesses operate within permissible voltage ranges.

- Harmonic Reduction: AHFs play a crucial role in reducing harmonic distortions, thereby helping industries meet limits set by regulatory bodies. This reduction not only avoids penalties but also ensures smooth operations.

- Power Factor Improvement: Poor power factor not only hampers efficiency but can also lead to regulatory non-compliance. AHFs contribute to power factor correction, aligning businesses with power factor requirements.

Benefits Beyond Compliance

While regulatory compliance is a significant driver, the benefits of AHFs extend beyond avoiding penalties:

- Mitigation of Penalties and Legal Issues: By integrating AHFs, businesses pre-emptively mitigate the risk of penalties, fines, and legal action due to non-compliance with power quality standards.

- Operational Continuity: Regulatory violations can lead to disruptions, downtime, and loss of productivity. AHFs' contribution to stable power quality ensures operational continuity, a critical advantage for businesses.

- Equipment Longevity: Harmonic distortions can lead to premature equipment failures. AHFs extend equipment lifespan, reducing the need for costly replacements and maintenance.

- Cost Savings: The optimisation of power quality achieved through AHFs leads to reduced energy consumption and lower electricity bills, providing an attractive return on investment.

Implementing Active Harmonic Filters

Successful implementation of AHFs involves strategic planning:

- Regulatory Assessment: Understand the specific regulatory requirements applicable to the industry and region. This provides clarity on the target parameters for power quality.

- Harmonic Profiling: Conduct a comprehensive harmonic assessment of the electrical system to identify the harmonic distortion levels. This informs the capacity and configuration of AHFs required.

- Customised Solutions: Collaborate with AHF experts to design solutions tailored to the industry's unique needs. These solutions optimise performance and compliance.

- Professional Installation: Proper installation by experienced professionals ensures seamless integration and adherence to performance standards.

- Ongoing Monitoring: Regular monitoring and maintenance ensure AHFs continue to meet regulatory requirements and perform optimally.

Quality Energy: Power Quality Solutions Experts Since 1989

Quality Energy understands the intricacies and importance of power quality for businesses to save on energy costs and improve energy efficiency. Quality Energy understands the intricacies and importance of power quality for businesses to save on energy costs and improve energy efficiency. Quality Energy manufactures all our power quality equipment in our manufacturing hub at Moorabbin, Victoria. We partner with premium electrical components manufacturers who are leaders in the field, enabling the creation of a new generation of Quality Energy Active Harmonic Filters that are flexible yet do not compromise on performance.

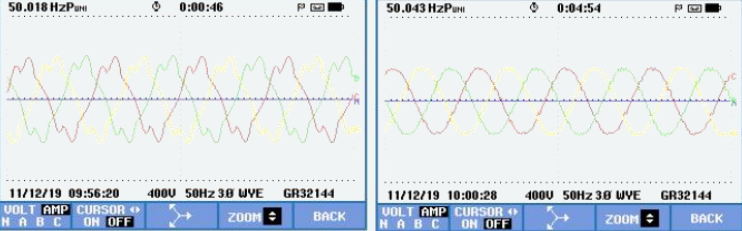

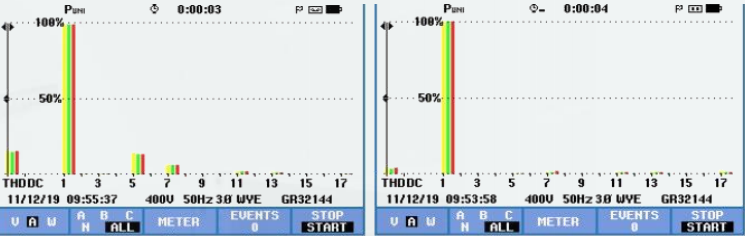

Quality Energy's Active Harmonic Filter in Action

The graph below is a use-case scenario of the Total Harmonic Distortion (THDi) for three phases. Before installing the AHF, the Total Harmonic Distortion (THDi) for three phases was 15%. After installing and commissioning Quality Energy’s Active Harmonic Filters, the THDi was reduced to 3%, a significant reduction in harmonics:

Conclusion

In the face of rising costs and productivity pressures, Active Harmonic Filters are your allies in energy efficiency and reducing your energy costs. Beyond their prowess in power quality enhancement, AHFs unlock a realm of financial benefits by optimising energy consumption, reducing overheads, and extending equipment lifespans. By embracing Active Harmonic Filters, Australian industries can move towards a highly efficient operations, heightened profitability, and a greener future.

Since 1989, Quality Energy is a power quality and energy efficiency solutions provider and manufacturer. Our mission is to help businesses solve the problem of ever-increasing energy costs and inconsistent, unreliable power supply.

Give us a call on 1800 736 374 or

send us an email to discuss your energy efficiency project.

Related news