Save on Business Insurance Premiums with Thermal Imaging

Thermal imaging is increasingly being used by businesses to reduce their commercial insurance premium. A thermal imaging survey of your switchboards can help you establish a low-risk working environment and effective fire reduction strategies. That is why insurance companies are progressively including thermal imaging as an essential requirement for commercial premises' fire risk assessment.

What Are the Benefits of Thermal Imaging for Your Business?

Thermal imaging can pinpoint trouble areas before problems arise. Using a specialised camera to measure infrared radiation emitted by an object, thermal imaging can detect hot spots in electrical wiring and connections generally traced to high-resistance areas with multiple causes of failures.

Other benefits of thermal imaging include:

- measure temperature variations accurately

- accurately target areas that need repair

- reduce unscheduled outages

- increase efficiency of maintenance programs

- document faults for corrective action or reporting

- reduce the risk of expensive equipment damage from electrical damage

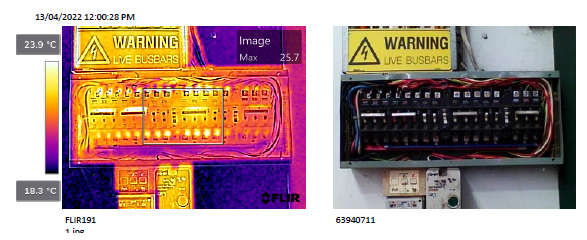

Example of Hazards Identified via Thermal Imaging

During our recent thermographic survey for an industrial client, we identified a couple of hazards in their ageing sub-board that - if neglected long enough - would become a serious fire hazard. Our world-class thermal imaging gun detected the issues by assessing the level of infrared radiation emitted by the object, regardless of the lighting condition. Our technicians then analysed the images and data collected, before providing a comprehensive report to our clients with recommendations. This process enabled our client to make informed economic and safety decision on the service and repairs required.

An electricity spark is one of the most significant contributors to fires in Victoria.

Thermal imaging is a non-invasive method to uncover any problem areas efficiently and safely, before it is too late. It is recommended to conduct thermal imaging once a year, or when moving into a new business premise.

The Quality Energy Promise

Quality Energy has been helping businesses reduce their energy costs for over 30 years. in fact, servicing and maintenance was how we started. Over the years, we have helped hundreds of Australian businesses save over thousands of dollars each year in electricity cost, and mitigate costly production shutdowns caused by electricity-related machinery and equipment malfunction.

Prevent property and financial loss by asking about our

thermal imaging and preventative maintenance services today.

Related news