On This Page:

- What is a Static Var Generator (SVG)?

- Why Improve Power Factor?

- Why Choose a Static Var Generator?

- How a Static Var Generator Works

- Static Var Generator (SVG) vs Capacitor Bank: Key Differences

- Are Static Var Generators applicable in all industries and sectors?

- Benefits of Quality Energy's Static Var Generator

- Advanced Power Factor Correction and Efficiency

- Dynamic Reactive Power Compensation

- Combine With Active Harmonic Filters for Hybrid Solutions

- Rapid Response Time For Voltage Stability

- Low Footprint and High Safety

- Flexibility for High-Voltage and Low-Voltage Systems

- Why Choose Quality Energy for Your SVG Solutions?

- Could a Static Var Generator Be Right for You?

What is a Static Var Generator (SVG)?

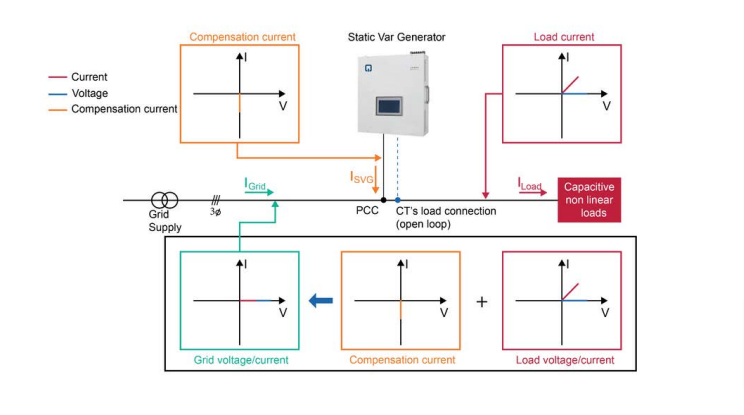

A Static Var Generator (SVG) is an electronic reactive power compensation system for capacitive and inductive power. It has the same operating principle as an active filter; the SVG injects a current in the opposite direction to counteract the installation's non-useful inductive and capacitive power.

They are invaluable in industrial and commercial applications and high-demand environments like renewable energy systems, manufacturing plants, and healthcare settings.

Why Improve Power Factor?

A low power factor means you are drawing more current (electricity) than you need. The Australian Energy Regulator allows electricity retailers to penalise businesses for the extra demand on the electricity grid. If your most recent power bill has a higher than expected charge for kVA, then your power factor is probably the cause.

Poor power factor can be improved by installing Power Factor Correction (PFC) or

Static Var Generator (SVG) equipment to correct energy supply inefficiencies, reduce the total current and apparent power (kVA) demand on the electricity network, and bring the power factor close to 1 (unity).

Why Choose a Static Var Generator?

Static Var Generators offer the ultimate solution to issues in power systems by dynamically compensating for reactive power caused by reactance in electrical load currents.

Power Factor Correction equipment is suitable for businesses with relatively stable loads that don’t require instantaneous, real-time, or highly dynamic reactive power control. PFC systems are cost-effective and work well for applications with minimal load variation or slow changes in power demand.

On the other hand, Static VAR Generators (SVGs) are advanced systems designed for continuous, dynamic power factor correction. They excel at providing instantaneous, real-time control of reactive power and maintaining three-phase load balance, making them ideal for facilities with rapidly changing or unbalanced loads, such as manufacturing plants, renewable energy installations, or systems with high harmonic distortions.

When alternating current (AC) systems encounter inductive or capacitive currents, they create inefficiencies like a low fundamental power factor and voltage drops.

SVGs directly address these issues by monitoring and correcting the phase angle difference between electric currents and voltage waves.

Active Harmonic Filters (AHF) can address the high current distortion issues of power quality. However, it can be an expensive solution to multiple power quality problems. We offer an economical hybrid solution combining the AHF and SVG features.

Compared to traditional capacitor banks, SVG technology provides faster response times, smaller space and volume requirements, and superior handling of harmonics caused by nonlinear loads like electric motors and variable-frequency drives (VFDs).

How a Static Var Generator Works

Static Var Generators operate based on AC power principles, using advanced power inverter and Insulated-Gate Bipolar Transistor (IGBT) technology to address inefficiencies in electrical current dynamically.

Detection and Analysis: Monitors the system's phase angle difference between voltage and current. This data helps the SVG understand whether the current is lagging or leading the voltage (caused by inductive or capacitive loads).- Reactive Power Injection: The SVG injects a calculated amount of reactive power into the electrical load, compensating for excessive lagging or leading current and stabilising the angle difference.

- Waveform Adjustment: By correcting the phasor relationships (between voltage and current vectors), SVGs ensure a power factor closer to unity and minimises excess power draw.

Static Var Generator (SVG) vs Capacitor Bank: Key Differences

While Static Var Generators (SVGs) and capacitor banks improve power quality and compensate for reactive power, they differ significantly in technology, functionality, and application. Here's a comparison:

| Feature | Static Var Generator (SVG) | Capacitor Bank |

|---|---|---|

| Feature | Uses a voltage-source converter (VSC) to generate or absorb reactive power dynamically. | Consists of fixed or switched capacitors for reactive power compensation. |

| Response Time | Extremely fast, with a response time of less than 10 milliseconds. | Slower, with delays in switching operations (step-based). |

| Reactive Power Control | Provides real-time, continuous, and precise compensation for both inductive and capacitive loads. | Provides step-wise compensation, limited to capacitive load correction only. |

| Harmonic Mitigation | Can help reduce harmonics when combined with harmonic filtration systems. | Does not address harmonics and may contribute to harmonic resonance. |

| Power Factor Correction | Achieves near-perfect correction (unity power factor). | Improves power factor but is less precise, especially under dynamic loads. |

| Maintenance | Low-maintenance and long-lasting due to the absence of large mechanical components. | Requires more frequent maintenance due to aging and potential failure. |

| Cost | Higher initial cost but provides better long-term ROI through efficiency and lower energy costs. | Lower upfront cost but can have higher operational and maintenance costs over time. |

| Applications | Ideal for dynamic, variable loads such as industrial systems, renewable energy setups, and smart grids. | Suitable for simpler, static systems with steady reactive power requirements, like conventional industrial or utility systems. |

Are Static Var Generators applicable in all industries and sectors?

Static Var Generators are applicable in commercial and industrial settings that have high electricity demand, such as:

- Power distribution system

- Manufacturing

- Healthcare settings

- Oil and gas

- Paper mills

- Data Centres

- Heavy industries

Benefits of Quality Energy's Static Var Generator

Advanced Power Factor Correction and Efficiency

A poor power factor caused by reactive power can

inflate kVA charges on your power bill. Quality Energy's SVGs are tailored to each business or organisation to dynamically adjust the system to correct leading or lagging currents, achieving a close-to-unity power factor. The result is optimised energy usage and enhanced system efficiency.

Dynamic Reactive Power Compensation

Quality Energy's Static Var Generators act as controlled current sources. They can quickly absorb or emit the required reactive power by adjusting the amplitude and phase of the inverter output voltage or directly controlling the amplitude and phase of the AC side current. Whether caused by inductive reactive power or capacitive reactive power, SVGs ensure power supply consistency by compensating for these variations in real-time.

Combine With Active Harmonic Filters for Hybrid Solutions

Quality Energy's SVGs are manufactured to also function as active power filters, suppressing harmonic currents produced by nonlinear electrical loads like solar power inverters and industrial devices. This reduces electricity interruptions, improves power quality, and ensures a balanced power system.

Rapid Response Time For Voltage Stability

Quality Energy's SVGs operate with sub-5ms response times. They reliably maintain system voltage stability, regardless of sudden load variations or phase (waves) imbalances. This makes our SVGs ideal for critical electric power distribution applications in industries like utility frequency management and high-voltage direct current converters.

Low Footprint and High Safety

By eliminating the need for additional capacitor banks or electronic filters, Quality Energy's Static Var Generators reduce overall device volume and space usage by up to 2/3 compared to older technologies. They avoid resonance issues common in some series and parallel circuits, ensuring a safe and stable system.

Flexibility for High-Voltage and Low-Voltage Systems

Quality Energy's SVGs provide a scalable and impactful solution in high-voltage direct current (HVDC) systems, electric power distribution, or low-voltage and high-voltage environments. Their usability extends to transformer stations, power transmission networks, and other mission-critical setups.

Why Choose Quality Energy for Your SVG Solutions?

With over 35 years of experience as Australia's premier quality power electronics provider, Quality Energy is your partner for power factor correction and power quality improvement. Our Melbourne-based facility specialises in manufacturing tailored Static Var Generators that meet your exact requirements.

Whether you're working with renewable energy sources, electric motors, or demanding industrial systems, our team ensures proper on-site commissioning and excellent customer support.

Could a Static Var Generator Be Right for You?

Are you looking for a way to reduce inefficiencies and lower operational costs? Contact us today to schedule a

Power Quality Audit for your business! Let us determine if a SVG is the right solution to improve your electric power system and solve any power quality problems.

Related news

Related articles

Let’s talk!

Have a question or comment? Let us know.

Head office – Melbourne

Other Locations

New South Wales

Queensland

South Australia

Tasmania