Power Factor Correction Equipment That Works for Your Business – Today and Tomorrow

Cut energy costs and boost electrical performance with Quality Energy’s Australian-made Power Factor Correction Systems. Custom built to improve efficiency, reduce demand charges, and extend the life of your electrical infrastructure.

Whether you’re looking for a cost-effective, reliable unit or a scalable, high-performance system, our ECO and MOD models deliver the perfect balance of efficiency and longevity.

How Power Factor Affects Your Bottom Line

When your site operates with a low power factor, it draws more current than necessary, pushing up your kVA demand and inflating both capital and operational expenses. Often, you're paying for unused capacity, and your energy company may impose penalties for poor efficiency.

Investing in reactive power compensation is one of the most cost-effective ways to optimise your electrical infrastructure. The right solution can:

- Cut electricity bills by removing excess demand charges and penalty fees.

- Free up capacity on your existing network, avoiding costly infrastructure upgrades.

- Stabilise voltage and enhance overall equipment performance.

- Reduce wear and heat stress on switchgear, cables, and transformers; extending asset lifespan.

- Improve energy efficiency and support sustainability goals by lowering carbon output.

PFC improves voltage stability, which reduces equipment strain and lowers the risk of unplanned downtime.

As part of a broader

power quality management plan, we help businesses eliminate inefficiencies, enhance system reliability, and avoid long-term equipment damage. If your recent power bill includes a kVA demand charge or efficiency-related penalty, it's a strong signal your site could benefit from correction equipment.

Power Factor Correction Designed Around Your Business, Not Off the Shelf

At Quality Energy, one size never fits all. Every site has unique energy demands, space limitations, and performance goals. That’s why we design and manufacture tailor-made PFC units here in Australia using two proven design philosophies:

ECO Design – Simplicity Meets Smart Engineering

Our ECO PFC equipment delivers reliable performance at the lowest possible cost. By mounting all components directly onto the cabinet’s backing plate, this design minimises complexity and keeps pricing competitive - without compromising reliability.

This design isn’t just simple – it’s clever. Every component is strategically placed to optimise thermal management:

- Capacitors are positioned at the bottom of the backing plate, where they can operate at the coolest temperature possible.

- Low-loss, low-heat harmonic blocking reactors are mounted mid-side of the backing plate, keeping their heat away from critical components – capacitors and contactors.

- All live conductors are insulated and rated IP2X for the highest level of protection and safety.

With fewer moving parts and

compact footprint options, the ECO PFC is easy to install, commission, and maintain. It’s the perfect solution for systems up to

400kVAr, making it cost-effective while delivering robust performance.

Key advantages:

- Lower upfront cost through reduced cabinet complexity

- Optimised cooling and component placement

- Compact and reliable

- Quick installation and minimal maintenance

While the ECO offers a streamlined, cost-effective approach, some sites need a PFC system that can evolve over time. That’s where the MOD design comes in.

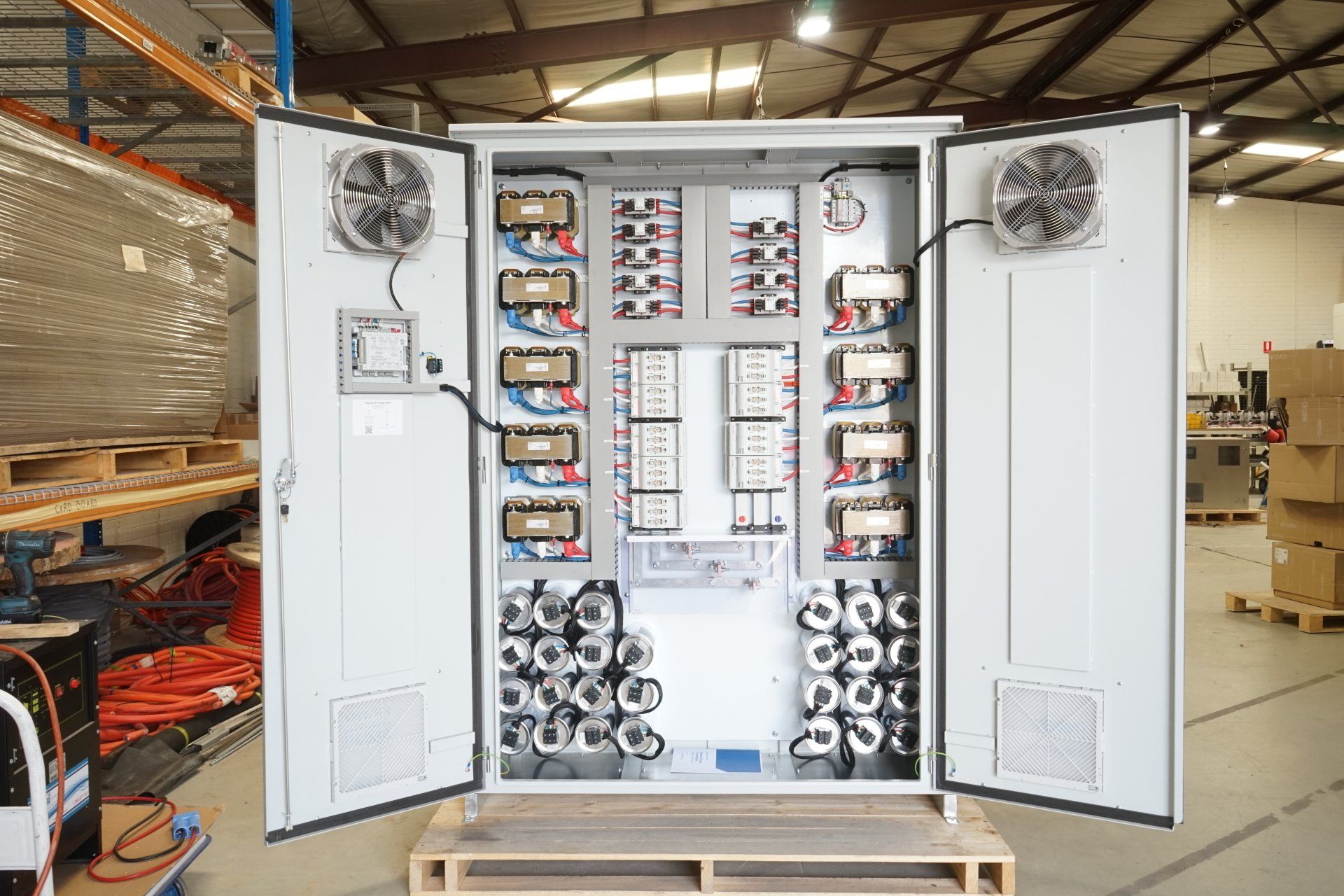

MOD Design – Flexible Power Correction for the Future

When sites demand higher capacity, scalability, easy serviceability, or advanced performance, our MOD PFC equipment takes centre stage. Built with individual modules that can be added, removed, or replaced as required, this premium configuration is ideal for systems above 400kVAr.

Innovation drives this design too. Each module is

fully segregated for enhanced safety and performance. The widened reactor section improves airflow and each module is installed on a slide out tray to make servicing and upgrades faster and easier - ensuring any downtime is kept to a minimum. The ability to scale up capacity on demand also future proofs your investment.

Key advantages:

- Scalable beyond 400kVAr

- Low-loss, low-heat reactors fully segregated for safety and performance

- Slide-out trays for streamlined servicing and upgrades

- Built for high-demand environments

ECO vs MOD At a Glance

| Feature/Benefit | Eco Design | Mod Design |

|---|---|---|

| Capacity Range | Up to 400kVAr | 50-1000kVAr |

| Design Philosophy | Simplicity and cost-efficiency | Scalability and premium performance features |

| Component Layout | All components mounted directly on a backing plate | Fully segregated modular sections |

| Thermal Management | Capacitors at bottom for cooler operation; reactors mounted mid-side to keep heat away from key components | Widened reactor section for improved airflow |

| Installation & Maintenance | Compact footprint, quick install, minimal maintenance | Slide-out modules for easy servicing and upgrades |

| Upfront Cost | Lower due to reduced cabinet complexity | Higher initial investment but expandable |

| Best Suited For | Sites wanting a reliable, low-cost solution for moderate loads | Sites needing high capacity, room for growth, or demanding environments |

| Scalability | Fixed capacity | Add-remove modules as required |

| Safety | All live conductors covered and rated IP2X | All live conductors covered and rated IP2X |

From lean, budget-friendly designs to fully modular, future-proof systems, our engineers will create a best-in-market PFC unit tailored to your site.

We balance performance, cost-efficiency, and innovation, ensuring you get the maximum return on your investment.

Built to Australian Standards, Backed by Proven Quality

At Quality Energy, every power factor correction system is engineered and manufactured in Australia to meet the highest industry benchmarks. All units are fully compliant with relevant AS/NZS standards and tailored to meet specific local supply authority requirements, ensuring safe, reliable integration into your electrical network.

Before leaving our facility, each unit undergoes comprehensive factory testing, including functional verification, thermal performance checks, and stringent safety assessments. This ensures your equipment performs exactly as specified, from the moment it's powered on.

Once delivered, our expert team handles on-site commissioning, calibrating the system to your site’s load profile and validating its performance under real operating conditions. This hands-on approach guarantees compliance, long-term performance, reliability, and peace of mind.

We have commissioned power factor correction units in Sydney, shipped PFC equipment across to New Zealand, and custom built power factor correction systems for large Adelaide manufacturers.

Trusted by Industry Leaders for Power Factor and Energy Efficiency Gains

From High Demand Charges to Six-Figure Savings – Bulla Dairy Foods

When Bulla Dairy Foods asked Quality Energy to reset their peak demand charges, we delivered a complete power quality upgrade:

- 1 × 625 kVAr PFC unit

- 2 × 350 kVAr PFC units

- 1 × 600A and 3 × 300A Active Harmonic Filters (AHFs)

The Outcome:

- Power factor lifted from 0.91 to 0.99 at one site and 0.93 to 0.99 at the other

- Harmonics effectively eliminated, reducing risk of equipment damage

- Over $660,000 in projected savings over 10 years from PFC units alone

$70,000 Annual Savings for SunRice with Custom Outdoor PFC

Facing a surge in energy costs, SunRice identified a poor power factor as the cause. They needed a 900 kVAr, outdoor-rated, side-entry PFC system with an 1800A main switch. A complex specification few could deliver.

The engineering team at Quality Energy designed and installed 2 × triple-door, outdoor-rated IP56 PFC units, each made up of 18 × 50 kVAr stages.

The Outcome:

- Power factor improved to reduce demand charges

- ~$70,000 in annual electricity savings

- Increased energy efficiency and reduced carbon footprint

- Follow-up project: custom 300 kVAr PFC unit to expand capacity and further cut operating costs

Frequently Asked Questions

What our customers say

Related articles

Stop Paying For Power You Don’t Use & Start Saving Today

Get in touch with the team at Quality Energy for a no obligation chat about our power factor correction equipment, and how we can help your business.