Power Factor Correction Equipment

World-leading reactive power compensation solutions for your business.

At Quality Energy, we understand the importance of optimising energy efficiency for your business. Our world-leading power factor correction equipment and solutions can raise your business efficiency, lower your carbon footprint, and reduce your risk of equipment failure. This translates to significant savings on your energy bill, reduced downtime, and improved overall performance.

Learn more below about our power factor promise and how we can assist you with power factor correction.

What is Power Factor?

Power Factor is a measure of how effectively your equipment is using electricity. It's calculated as the ratio of real power to total power and is expressed as a numerical value between 0 and 1.0. A good power factor (0.98-0.99) means your equipment is using energy efficiently, while a low Power Factor (anything below 0.98) means you're wasting energy.

If your power factor is 0.7, you’re using - and being charged for - 30% more power than you should be. The closer your power factor is to 1, the more efficiently the business is consuming electricity.

Inefficient electrical systems use a large quantity of ‘reactive’ power (kVAr), representing the power lost in the operation of inductive equipment such as transformers. This invariably increases the total power load, also known as apparent power (kVA), and reduces your overall power factor.

Why is Power Factor Correction Equipment Important?

A low power factor means you're drawing more current than you need, resulting in higher capital expenditure and operating costs, such as increased demand charges, as you're paying for extra power that's not being used.

Running motors, machinery, and other equipment uses a lot of power. The electricity needed to keep things running is referred to as active power or real power. It is measured in kilowatts (kW) on your electricity bill.

Traditional electrical equipment, such as motors and transformers, can lead to high energy losses and reduce the overall efficiency of the system. These losses can manifest as heat, vibration, and noise, which can lead to premature wear and tear on the equipment. Conventional equipment may also require more frequent maintenance, as it is more prone to overheating and mechanical failure.

Our power factor correction (PFC) equipment can help you improve your power factor, decrease wear and tear on your equipment, reduce your energy usage, and lower your electricity bills.

The Australian Energy Regulator allows electricity providers to penalise businesses for extra demand on the electricity grid. If your most recent power bill has a charge for kVA (kilo-volt-ampere), then your power factor is probably inflating your bill.

How Does Power Factor Correction Work?

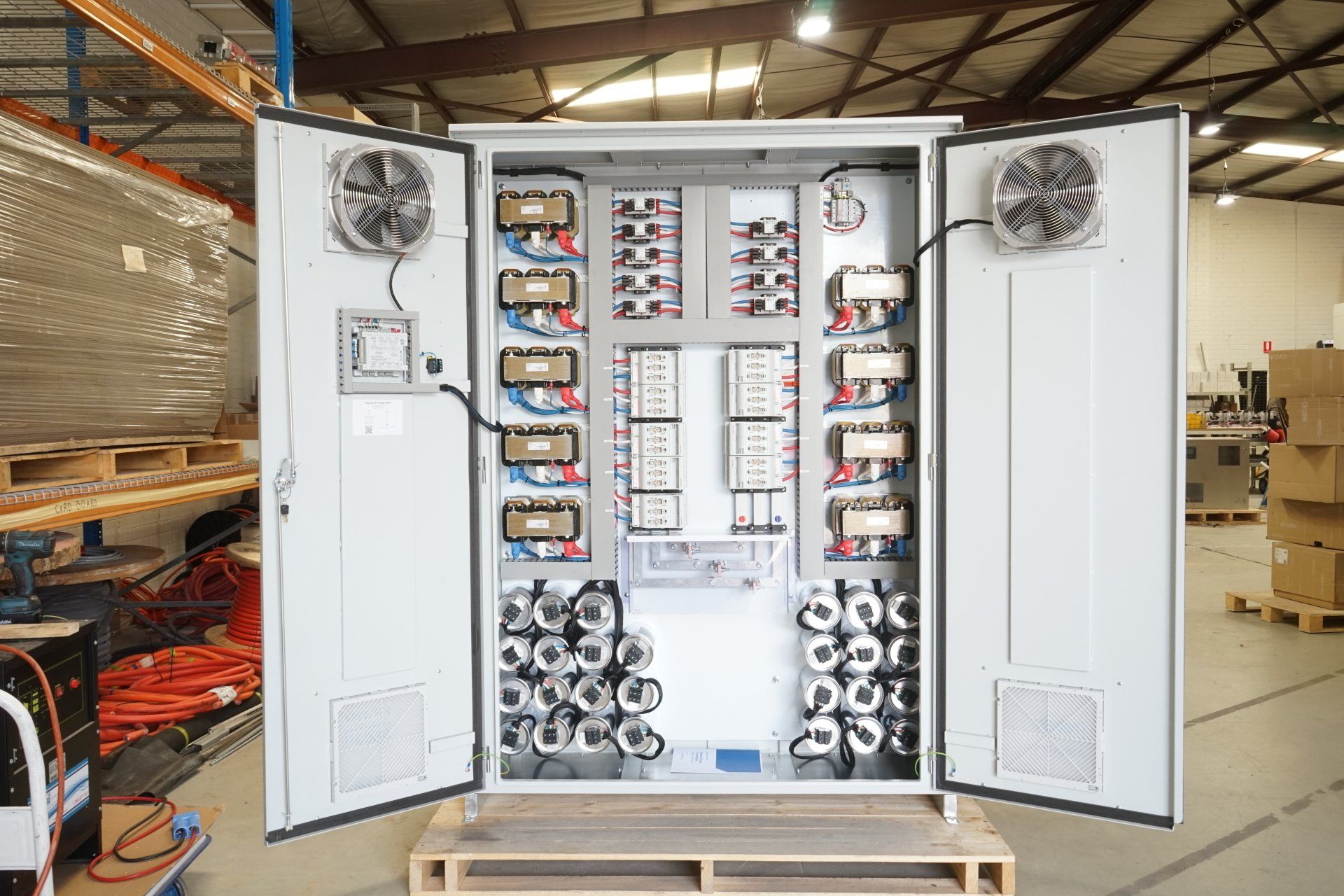

PFC equipment compensates for reactive power and improves the ratio of real power to total power. This is achieved by installing capacitor modules with reactors and a controller that acts as a buffer between the incoming power supply and the main distribution panel.

Learn more about how power factor correction works here.

Benefits of Installing Power Factor Correction Equipment

Our PFC units offer numerous benefits, including:

- A reduction in power consumed

- Lower energy bills

- Improved system capacity

- Reduced power losses and voltage drops

- Increased equipment lifespan

- Improved overall energy savings

To determine the best solution for your business, we recommend conducting a comprehensive power quality audit. Our team of experts will assess your energy usage and provide a tailored recommendation for correcting your power factor.

Custom Modular Power Factor Correction From Quality Energy

PFC is not a one-size-fits-all solution. Quality Energy has been Australia’s leading manufacturer of power factor correction equipment for over 35 years.

Installing a PFC unit is the most effective long-term solution for improving energy management. A PFC system consists of capacitor modules, reactors, and a controller that works as a buffer between the incoming power supply and the main distribution panel.

At Quality Energy, we offer a range of power factor improvement systems, including:

- Low Voltage (LV) and High Voltage (HV) units

- Custom solutions tailored to your business's energy profile

- Modular units for future expansion

Our power correction equipment decreases energy losses and improves the overall efficiency of your electrical system. Our solutions are manufactured with premium European components and built here in Melbourne, Australia. They are built to last, with a 3-year warranty on all standard systems. We also offer service and commissioning capability to our client sites.

Power Quality Correction for Enterprises, Industries & Businesses

Our PFC correction devices are designed to optimise your business's energy usage and reduce energy losses.

We offer a range of solutions, including:

- PFC units for single-phase and three-phase systems

- Harmonic filtering devices for reducing power factor correction requirements

- Line conditioning devices for improving the overall efficiency of your electrical system

By improving your power factor, you can improve system capacity and lower your bills. Our power factor units can help you:

- Reduce your peak demand charges

- Lower your overall energy consumption

- Improve your energy management

Our PFC units include online monitoring capabilities, allowing you to track your energy usage and system performance in real time.

Revolutionary Power Factor Correction System Built With Premium European Components.

Every component in a PFC unit works together to perform the work of several engineers 24/7, reducing your electricity demand and monitoring and collecting data for analysis.

Our revolutionary systems are engineered with:

- C-tick Australia standards

- Slide out trays in our modular units for easy and fast maintenance

- No access to live terminals for safe and secure operations

- Premium grade European components that have been proven over time to deliver greater results and reliability

- Full segregation of heat generating harmonic blocking reactors from capacitors, critical switching, and control equipment to ensure greater life expectancy for all components in the power factor correction unit.

- 3-year warranty on all standard systems

- Expandable units to cater for future growth of plant or increase in equipment

- Online monitoring

Power Factor Correction is the solution to energy wastage and optimising energy usage. Our solutions can help you reduce wasted power, lower your electricity bills, and improve your overall energy consumption.

FAQs about Power Factor Correction

Quality Energy is here to answer your queries. If your question is not listed below, please do not hesitate to contact our team, we would be happy to assist.

What our customers say

Related articles